ACCURACY MEASURED BY THE MILLIMETRE

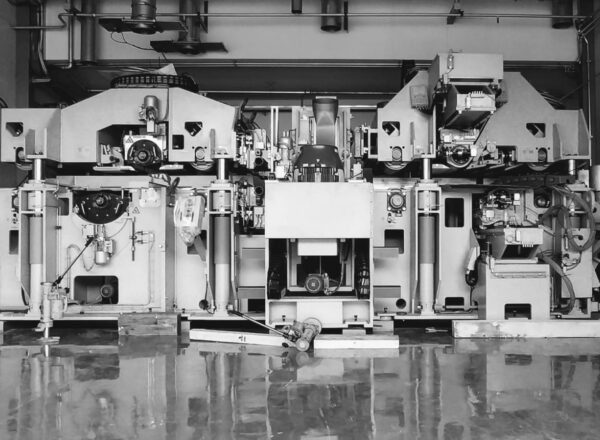

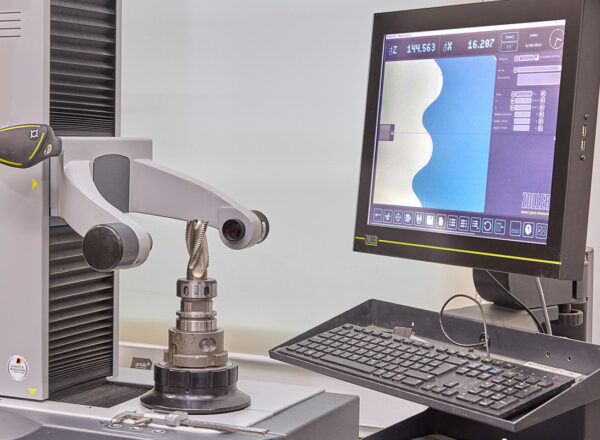

We use the most advanced CNC-based Hundegger K2i wood processing machine and the world’s largest log planer. Our machining quality and accuracy are incomparable, and we can implement even the most challenging wishes of our customers. The Hundegger machine is used to produce, e.g. various corner joints and beam structure details. It can also be used to make various special processing works and roof structures, which often remain visible and thus need to be accurate to the millimetre.

We can offer the best selection of logs and the largest laminated logs in the world.